Contract Capacity about ESS Battery

Contract capacity, often referred to as “basic electricity price” or “demand charge,” represents the fixed cost component that power enterprises incur for providing ready-to-serve capacity. Essentially, it’s a fee that customers pay based on their agreed-upon capacity or maximum power demand, separate from the actual energy they consume.

For example, consider an enterprise with a contracted transformer capacity of 500 KVA. If the local basic electricity charge is 20 yuan per KVA per month, then the company’s monthly capacity charge would be 500 KVA * 20 yuan/KVA = 10,000 yuan.

Mainstream Applications of ESS Battery

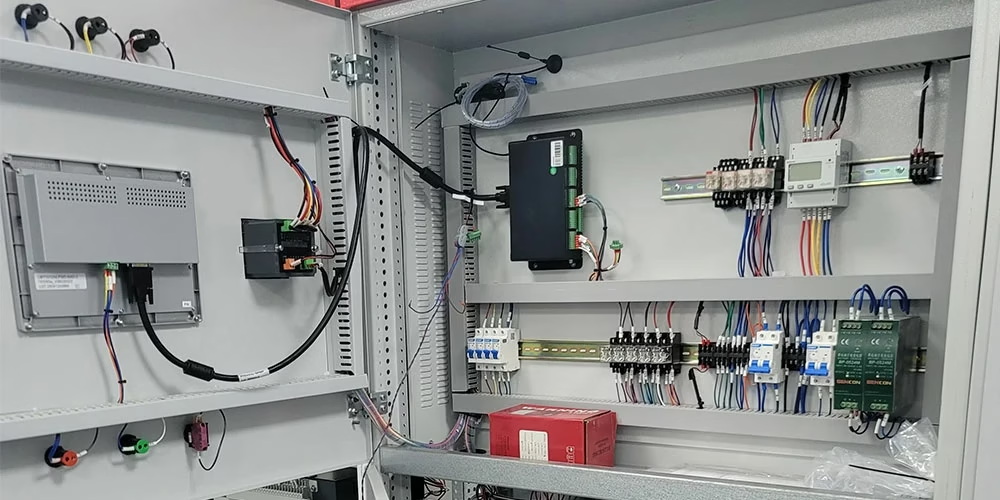

A typical Industrial and Commercial Energy Storage System (C&I ESS) integrates several key components. These primarily include the energy storage battery, the energy conversion system (PCS), along with control and monitoring systems.

When we look at the battery itself, the sector utilizes various technologies like electrochemical energy storage, supercapacitors, and even gravity energy storage. However, lithium-ion batteries currently dominate the electrochemical energy storage field. Their widespread adoption, especially in commercial and industrial settings, stems from a compelling set of advantages: high energy density, exceptional charge and discharge efficiency, and very rapid response times.

Applications of ESS Battery

Industrial and commercial storage systems are proving critical in several key areas:

- High Energy-Consuming Enterprises: First and foremost, sectors like metallurgy, cement, and chemicals, which have intensive power needs, greatly benefit. These enterprises can strategically use energy storage to manage their maximum power demand, thereby significantly reducing their electricity bills.

- Communication Base Stations: Furthermore, sites like communication base stations, which require an extremely continuous power supply, are ideal candidates. Many already have UPS systems in place, and integrating a C&I ESS allows for daily cycling of the battery. This dual function ensures the communication system’s stable operation while also optimizing energy costs.

- Data Centers: Similarly, data centers have zero tolerance for power interruptions. Here, C&I ESS can be custom-configured with low-voltage ride-through capabilities. This crucial feature prevents costly data loss and system downtime that can result from minor grid fluctuations.

- Charging & Battery Swapping Stations: In the electric vehicle ecosystem, these systems are highly versatile. At charging stations, they can be used for “virtual capacity expansion,” enhancing the site’s charging efficiency and service capability without expensive grid upgrades. Meanwhile, battery swapping stations inherently function as large-scale energy storage stations themselves.

- Industrial Parks: Finally, industrial parks represent a major application scenario. Operators can implement centralized or distributed storage systems to achieve efficient energy management and optimal utilization across the park. It’s important to note, however, that their deployment is subject to the park’s overall energy demand limits.

Air-Cooling in Energy Storage Systems

Air-cooling is a thermal management technology that relies on forced air convection to regulate battery temperature. In this system, fans actively move air across the surface of the battery cells to carry away excess heat.

This method is generally suitable for small-scale systems and applications with relatively low charge/discharge rates (typically below 0.5C). Its main appeal lies in a simple structure and low initial cost. On the downside, its primary limitation is relatively poor temperature uniformity across the battery pack.

Liquid-Cooling in Energy Storage Systems

In contrast, liquid-cooling employs a circulating coolant—such as an ethylene-glycol water solution—that flows through internal pipes or cold plates integrated within the battery modules. This design achieves highly efficient heat exchange directly at the source.

The standout technical feature of liquid cooling is its superior heat dissipation efficiency. Because of this significant performance advantage, the industry widely recognizes it as the mainstream future direction for energy storage thermal management, particularly for high-power and large-scale applications.