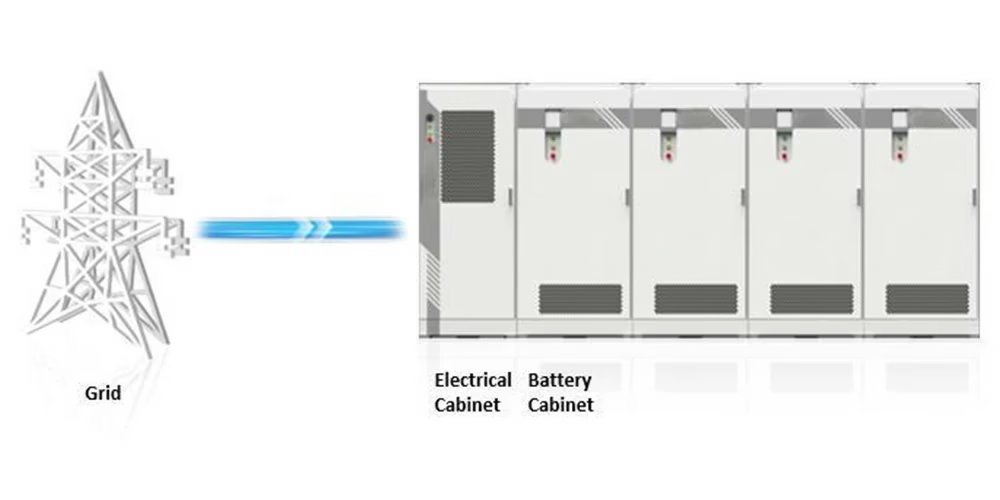

LVFU ESS System Description

LF-ESS261 is an industrial and commercial energy storage battery system that integrates a battery cabinet with an electrical cabinet. It employs a modular design and, furthermore, features rapid scalability in both power and capacity to accommodate diverse customization requirements. The battery cabinet houses 261 kWh energy storage battery clusters along with fire protection systems, liquid cooling systems, high-voltage boxes, and other related equipment. Meanwhile, the electrical cabinet contains components such as the PCS, EMS, MPPT, and STS, and it can actively provide tailored solutions based on specific needs.

Primarily, LF-ESS261 serves applications including energy storage projects, energy storage plus photovoltaic systems, integrated PV-energy storage-charging stations, and microgrids. In practice, it helps enterprises reduce electricity costs effectively by leveraging peak-to-valley price differentials, participating in demand response programs, and providing auxiliary grid services.

Typical application scenarios of LF-ESS

LVFU ESS Product features

Flexible capacity expansio

LF-ESS261 enables flexible capacity expansion on both the AC and DC sides to meet diverse requirements. For instance, the system can support the parallel operation of up to four battery cabinets with one 400V electrical cabinet. Consequently, this configuration can extend the system’s duration from the standard 2 hours up to 8 hours.

Higher protection leve

The battery compartment achieves an IP55 protection level, allowing it to adapt to various application environments. Additionally, the standard cabinet features a C3H anti-corrosion grade, which meets the demands of most settings. Furthermore, the system supports customized higher grades such as C4 and C5 for more challenging conditions.

Efficient liquid cooling system

- Each battery cabinet is equipped with a liquid cooling system, which can thermally manage the battery cluster, enabling the battery to operate at the most suitable temperature range, improving the temperature balance in the cabinet and prolonging the service life of the system.

- The liquid cooling system is isolated from the battery system in separate warehouses, and the liquid cooling unit is located at the lower part of the cabinet, which effectively avoids the risk of leakage of the liquid cooling unit and greatly improves safety and reliability.

- By adding an anti-condensation device, the dew point temperature can be effectively reduced and the possibility of condensation can be reduced.

Multi-level fire protection

Every battery cabinet implements a comprehensive suite of fire protection measures. These include detection, suppression, explosion-proofing, and explosion venting systems. Together, these layers of protection work to maximize failure protection for the battery cabinet.